Torpedo Piles

Torpedo Piles

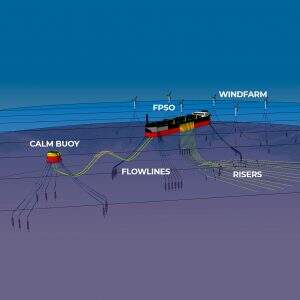

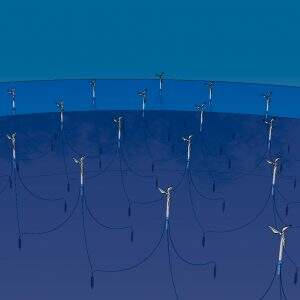

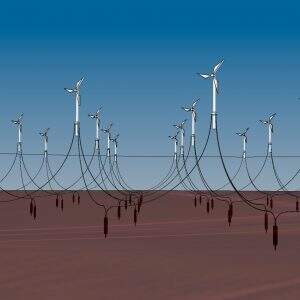

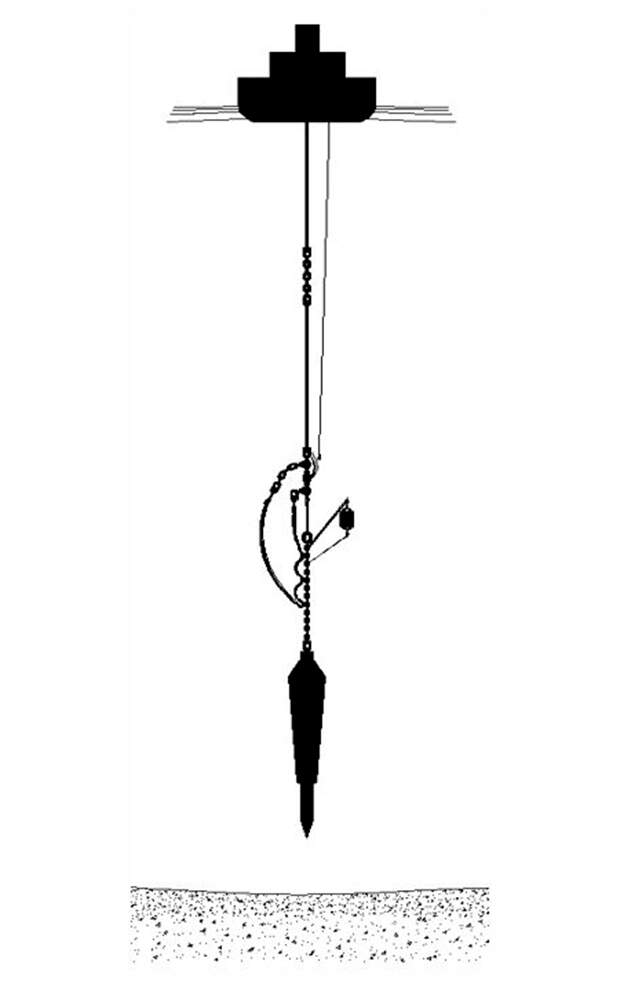

Torpedo Piles are high-capacity anchors that have a low installation cost. Delp Mooring has the technology to design and manufacture these piles. This is an efficient system that optimizes the mooring capacity of floating structures and offshore windfarms installations.

From soil analysis, through structural design and from offshore assets manufacturing to installation, Delp Mooring delivers a complete solution.

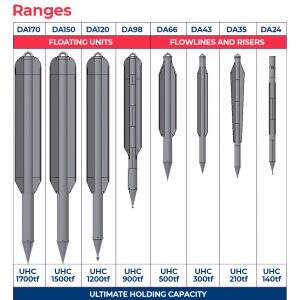

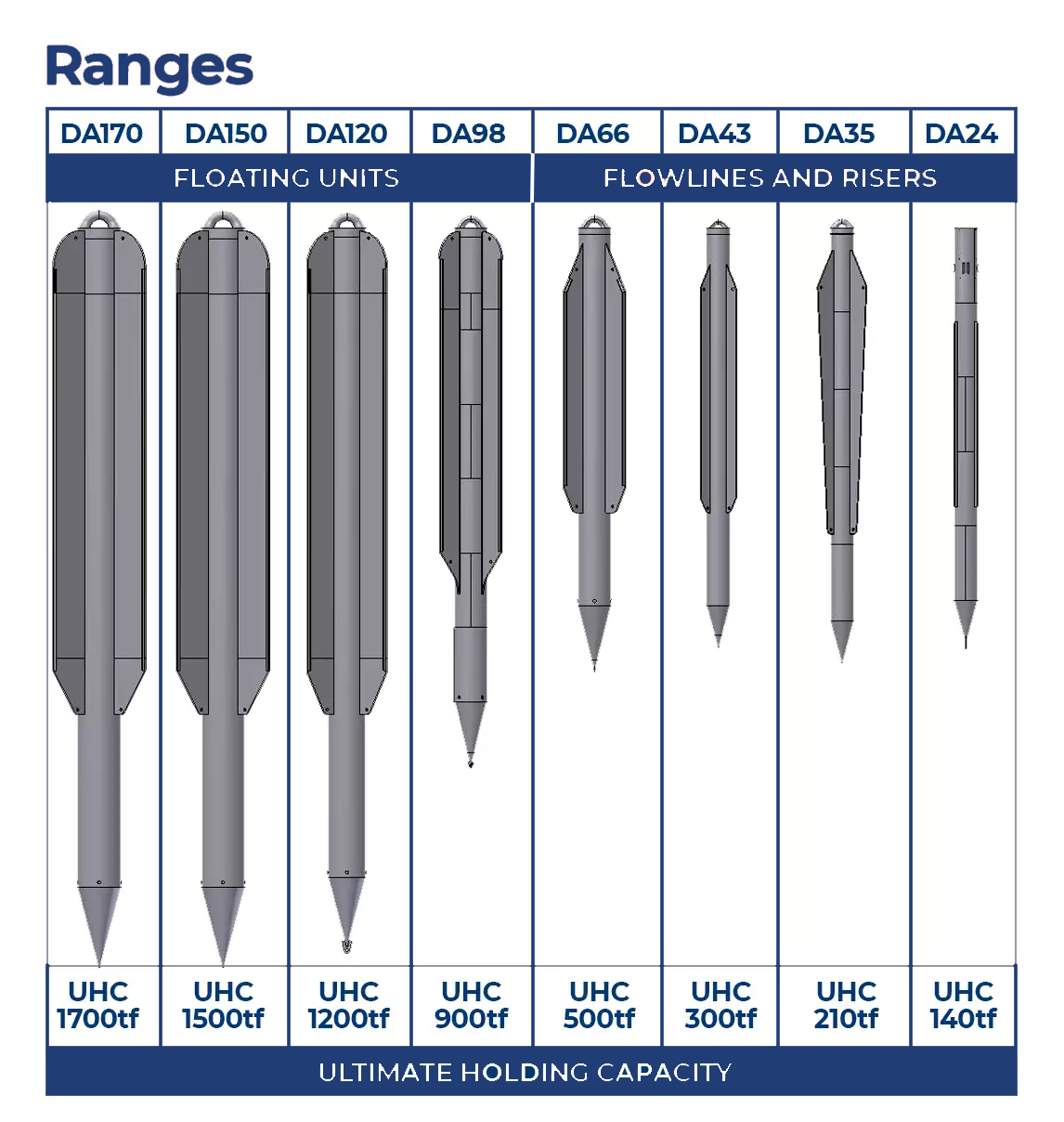

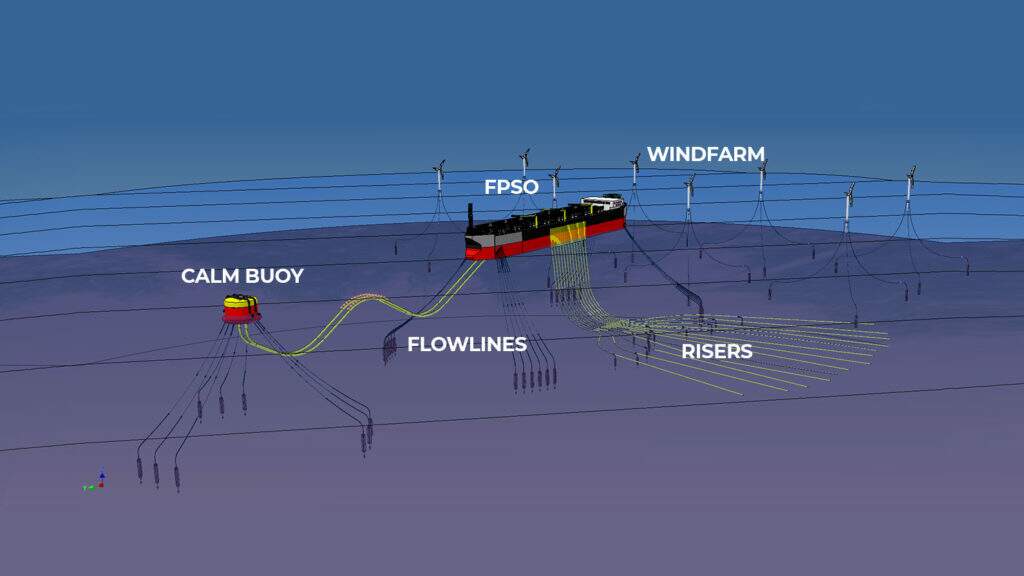

Delp Mooring currently manufactures and installs 8 different types of Torpedo Piles. Each of them has the capacity to anchor different types of equipment in the oil and gas sector and also deep-water wind turbine in the power generation sector. It is the most cost-effective, field-proven option in offshore deep-water Anchoring System, applied to Production Units, Rigs, Steel Risers, Flexible flowlines, Umbilical and Wind farms. Proven technology with numerous Torpedo Piles installed.

Engineering Services

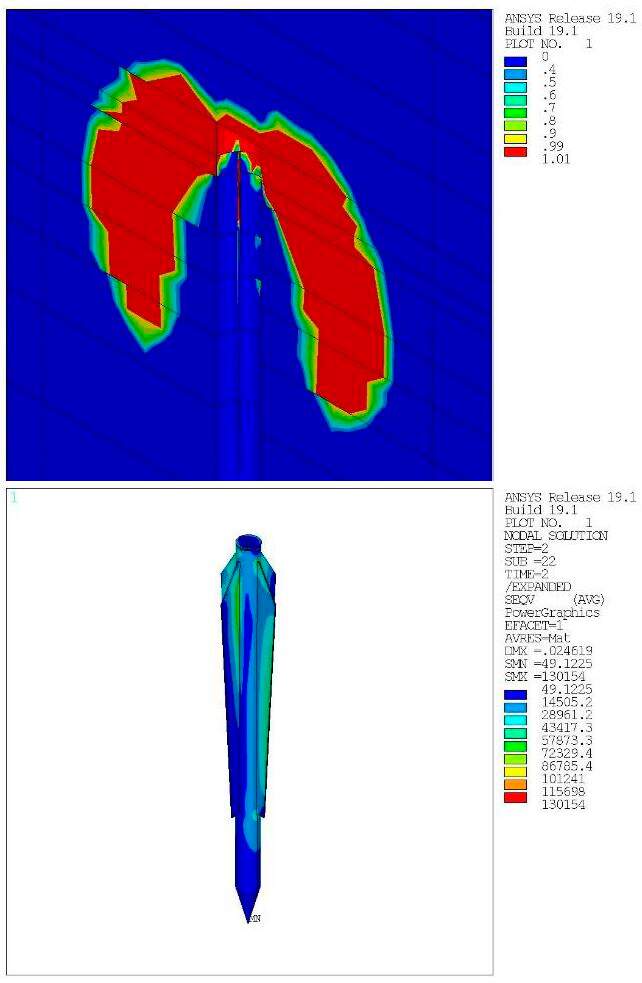

Delp Mooring provides engineering solutions based on the interaction analysis of the Torpedo Pile and soil. Therefore, it is possible to set the adequate Torpedo Pile to support the design load. In addition, Delp Mooring is able to provide the mooring and installation engineering.

Installation Engineering

Soil Interaction Analysis

O&G

ADVANTAGES

- Lower Anchor Price (40%)

- Higher resistance for vertical loads

- Layout optimization

- Regular truck for onshore logistics

- Flexible installation system

- Field Proven installation method

- Simpler vessels, less working tools

- Easily adjustable for the client Asset

- Less transit time: up to 14 piles per trip

- Accuracy on anchoring Target Spot

- Controlled parameters (Embedment, tilting)

- No seabed trenching after installation – holding capacity kept for all lifetime

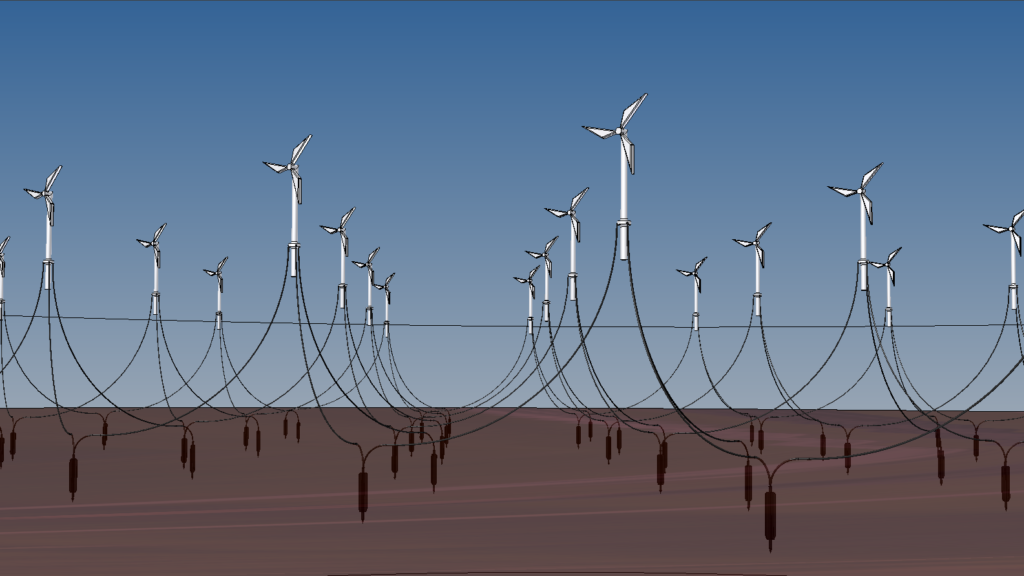

Windfarm

ADVANTAGES

- Anchoring efficiency

- High production rate (deliver up to 8 piles per month)

- Installation lead time

- Subsea Layout optimization (taut leg mooring type)

- Lower Anchor Price (40%)

- Cost-efficient installation (1 Pile/Day)

- Higher resistance for vertical loads

- Regular truck for onshore logistics

- Flexible installation system

- Field Proven installation method

- Simpler vessels, less working tools

- Easily adjustable for the client Asset

- Less transit time: up to 14 piles per trip

- Accuracy on anchoring Target Spot

- Controlled parameters (Embedment, tilting)

- No seabed trenching after installation – holding capacity kept for all lifetime